Technique

Underwater welding can be separate into two types: dry (hyperbaric) welding and wet welding. Underwater wet welding directly exposes the diver and electrode to the water and surrounding elements.

The electric arc heats the workpiece and the welding rod, and the molten metal is transferred through the gas bubble around the arc. The electro current flow induces transfer of metal droplets from the electrode to the workpiece and enables positional welding by a qualified operator.

The presence of a gas bubble, which is formed around the arc, is a necessary condition for the existing of discharge welding. It occurs at the initial moment of welding when the electrode contacted with the surface by heating the contact place with the electro current. An arc is appear when the electrode had been separated from the bubble and this causes the further development of the process.

The arc burns in the closed volume of the gas bubble, which have formed due to the products of water dissociation, as well as the combustion and evaporation of the metal of the fuse electrode and the product. The volume of bubble is constantly changing due to the continuous process and gas formation.

Staff

Qualified staff is one of the most important components for quality wet welding. Our company pays special attention to the training of divers for maintaining high qualifications.

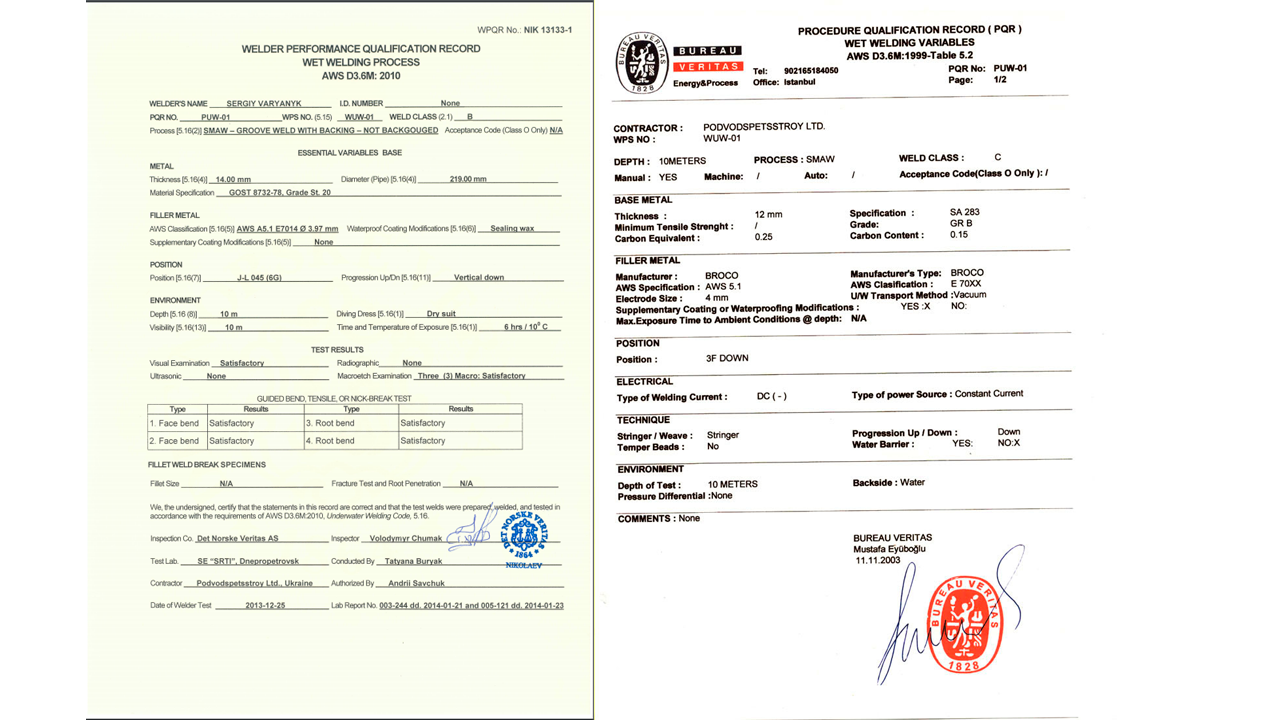

In accordance with our training method, the diver with at least 500 hours of practical diving operations is admitted to mastering the technology of wet welding. First, the candidates study the principles of topside welding, safety procedures and start practical training on mastering of topside welding. Over the years of our practice, we came to the conclusion that not all people are able to master this technology. According to the results of practical training, we select the most capable candidates, and they proceed to studying the principles of wet welding. After mastering of the definite position of the weld, the diver performs welding of test samples, which are further provided to the laboratory for testing and are subjected to tensile tests and bending tests; besides, macrostructural analysis of the welds is carried out. If the submitted samples pass the tests, the diver is admitted to mastering of the next position. It is rather long and energy-intensive process. Further, the diver may confirm his skill by producing the control samples in the presence of the surveyor of one of the world classification societies and gain the recognition from that society. However, it is only a part of the way. In order for your specialist not to lose his skills, he needs constant training or practice. Our diver welders take training courses at least two times during a calendar year and before performance of each contract. During the training period, the diver should confirm all specified positions of the weld. Our underwater welders carry out daily training at our base.

Wet welding video presentation.

As a result of our staff policy, our company has 6G and 3G divers-welders certified according to the international welding standard AWS D3.6M-2017. Our team has both qualified divers-welders and NDT specialists/engineers for development of WPS and welding quality control.

Our welders were certified by the classification community BUERAU VERITAS and DET NORSKE VERITAS for the most difficult welding position – 6G.